ABS Plus

OVERALL DURABILITY

A multifunctional material for desktop 3D printing, recommended especially for prototyping models thanks to its special properties such as increased hardness and reduced process shrinkage. What is more, printing will be easier and faster compared to standard ABS and does not require printing in a closed chamber. It can also be mechanically and chemically processed.

ABS PLUS will find application in the industry, where creating advanced prototypes and end-use parts require increased durability.

APPLICATIONS:

END-USE PARTS: containers, holders

PROTOTYPES: mechanical parts, architectural models

ELECTRONICS: covers, cases

DECORATIONS: lamps, vases

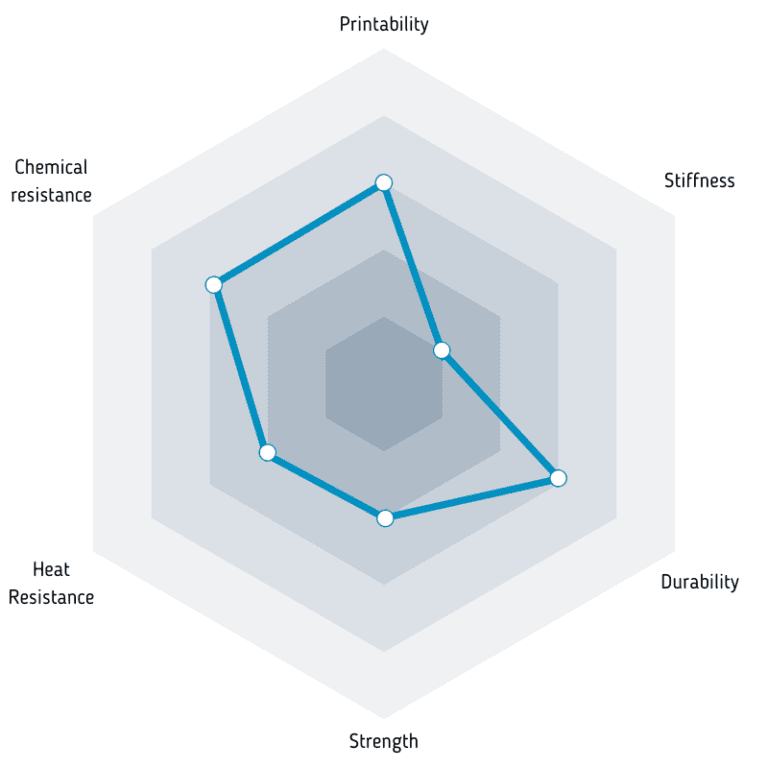

PROPERTIES:

Increased hardness and durability

High impact resistance

Resistance to high temperature and abrasion

Possibility of machining and chemical treatment

Possibility of printing in open printers

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

Nozzle Temperature

Bed Temperature

Closed Chamber

Fan

Flowrate

Printing Speed

Surface

Retraction (direct)

Retraction (bowden)

Retraction Speed

Drying Conditions

250-270°C

90-110°C

Recommended

0-10%

95-105%

35-60 mm/s

glass, kapton tape, ABS juice

2-3 mm

4-6 mm

20-45 mm/s

60°C / 4h

Colours

Gray

Yellow

Red

Blue

White

Black