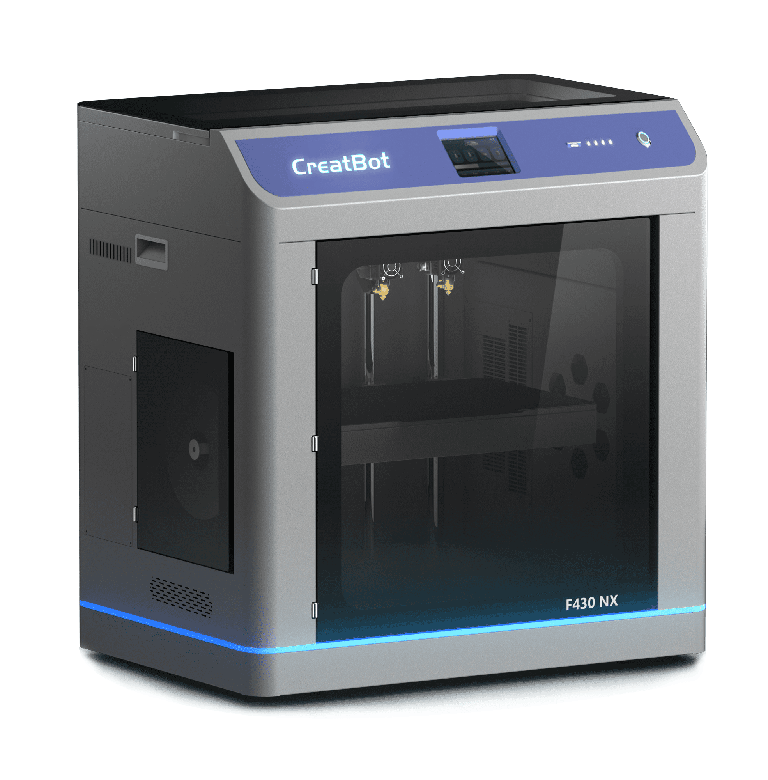

Creatbot F430 NX

F430 NX

A new generation of professional-grade high-speed 3D printer

The CreatBot F430 series has been proven to be one of the best-selling professional 3D printers, with a cumulative global sales volume of more than 5,000 units. Now, the new generation product F430 NX of this series has been released. It has a more advanced design concept and profound technical reserves, with powerful performance and no shortcomings. It has a brand-new appearance; high-precision machined parts are used as the structural framework; the independent dual-nozzle memory silicon carbide large-flow extrusion head enables it to be perfectly compatible with high-performance consumables and high-speed printing. The operation process is simpler, and the 24/7 operation is more stable. In the professional field, it will be your first choice.

What makes the F430 NX the most welcomed 3d printer product?

The CreatBot F430 NX is the powerful 3D printer with most advanced desktop 3D technology. It provides solutions for just about every application from concept to prototype and high performance material direct production. Its best-in-class technical specifications deliver performance you can rely on.

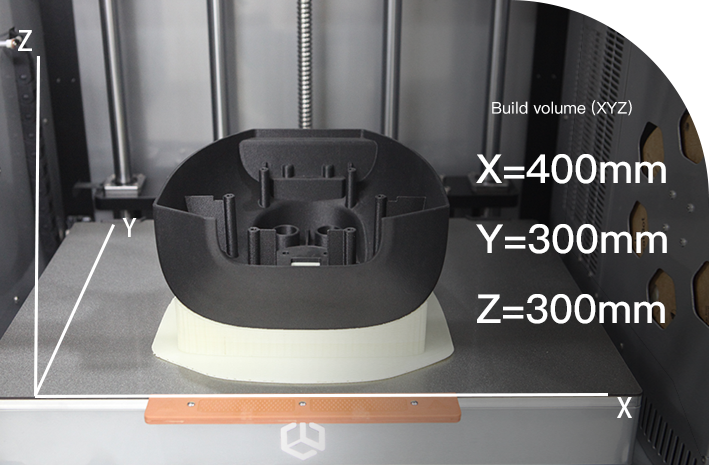

Big Build Volume

High Resolution

IDEX printing

Compatible Filament

Heat Control System

400*300*300mm

0.04mm

Single printing

Dual printing

Copy printing

Mirror printing

Consumer-grade:

PLA, PETG, PLA-CF, etc

Industrial-grade:

ASA, ABS, PC, Nylon, PET-CF, PET-GF, UltraPA-CF, etc

Support materials:

S-270, S-350, etc

Hotend 420°C dual

Hot Bed 120°C

Hot Chamber 70°C

1. POWERFUL EXTRUSION SYSTEM

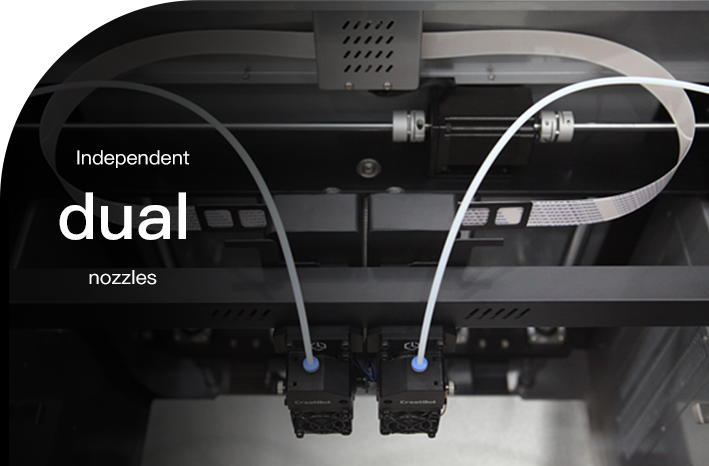

Independent Dual Extruders (IDEX)

Titanium alloy extrusion head

Quick-swap hotends

420°C silicon carbide nozzle nozzles

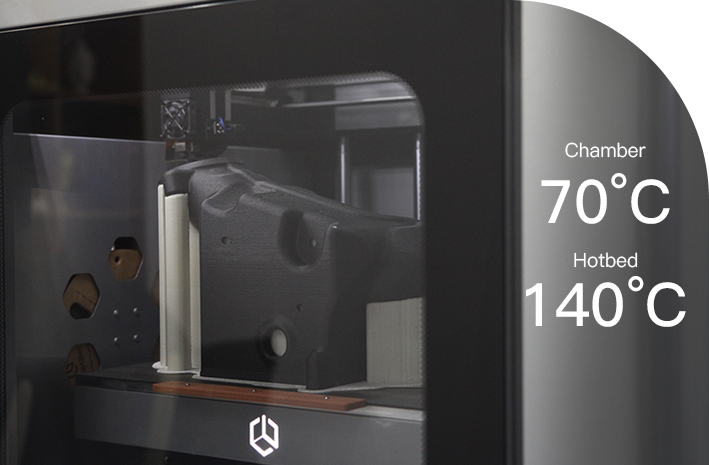

2. ACTIVE HEATED CHAMBER

Chamber up to 70°C

Heated bed up to 140°C

3. MASSIVE PRINT VOLUME

400*300*300mm (Single printing)

360*300*300mm (Dual printing)

225*300*300mm (Copy)

190*300*300mm (Mirror)

4. HIGH SPEED READY

Speed 100-300mm/s

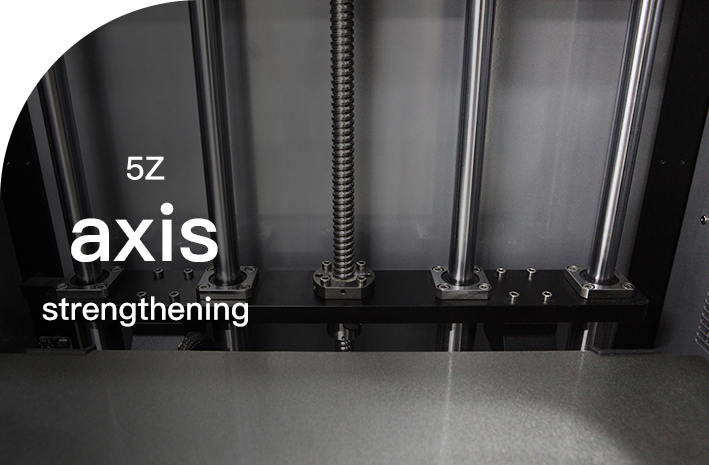

Z axis strengthening

5. MATERIAL OPERATIONS SYSTEM

Filament drying room 70°C

Auto Filament Switching

Engineering-grade materials

Carbon/Glass fiber ready

6. USER EXPERIENCE

Flexible build plate

Build-in Camera

5” capacitive touchscreen

Connectivity via WiFi or Ethernet

Status-breathing atmosphere light

7. SAFETY

50db working

HEAP and Carbon filter

Fault signal light

Thermal runaway protection

High temperature hotend 420°C

Using the latest technology of one-piece die-cast memory alloy hot end and super wear-resistant nozzle, temperature resistance up to 420°C. Compatible with PLA, ABS, ASA, PC, nylon, carbon fiber, and glass fiber materials. The nozzle aperture wear rate does not exceed 10% after printing carbon fiber materials for 2000 hours.

Independent Dual Extruders (IDEX)

This is the best solution for printing engineering-grade materials with independent support materials, ensuring the best quality of engineering-grade material printing. It also supports copy, mirror, and backup mode printing.

Big Build Volume

The printing size of single printing reaches 400*300*300mm, and the printing size with support materials reaches 360*300*300mm. The printing size is larger than that of most professional-grade products on the market.

Z Axis Reinforcement

The back side of the Z-axis is composed of a high-precision ball screw and 4 reinforced optical axes, with high-precision tight fit and synchronous movement. The surface of the model is uniform and free of impurities, improving the printing surface quality of engineering-grade materials.

Active Heating of the Hot Bed/Chamber

The active heated bed heating temperature reaches 140°C and the active chamber heating temperature reaches 70°C. It effectively prevents the shrinkage and cracking of engineering-grade materials, allowing ABS, ASA, PC, Nylon, UltraPA-CF, etc. to be perfectly formed and the mechanical properties to be maximized.

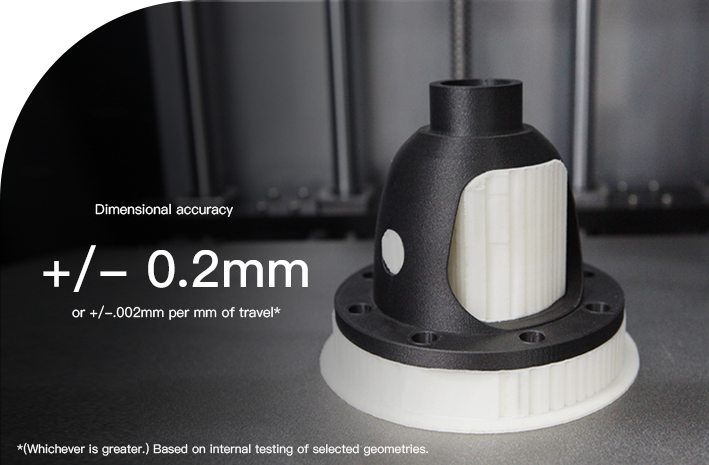

Superior Dimensional Accuracy

The F430 NX is specifically designed with a tight combination of high-precision machined structures to maintain dimensional accuracy and tight tolerances when printing the largest parts in engineering-grade materials. Not only does the F430 NX avoid warping and layer adhesion issues, but it creates massive parts with industrial-grade precision.

High-Resolution Touch Screen

Adopting a 5-inch high-resolution capacitive touch screen, it has no delay in operation, delicate touch, user-friendly interface and convenient operation and management.