Product Description

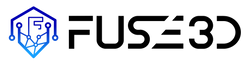

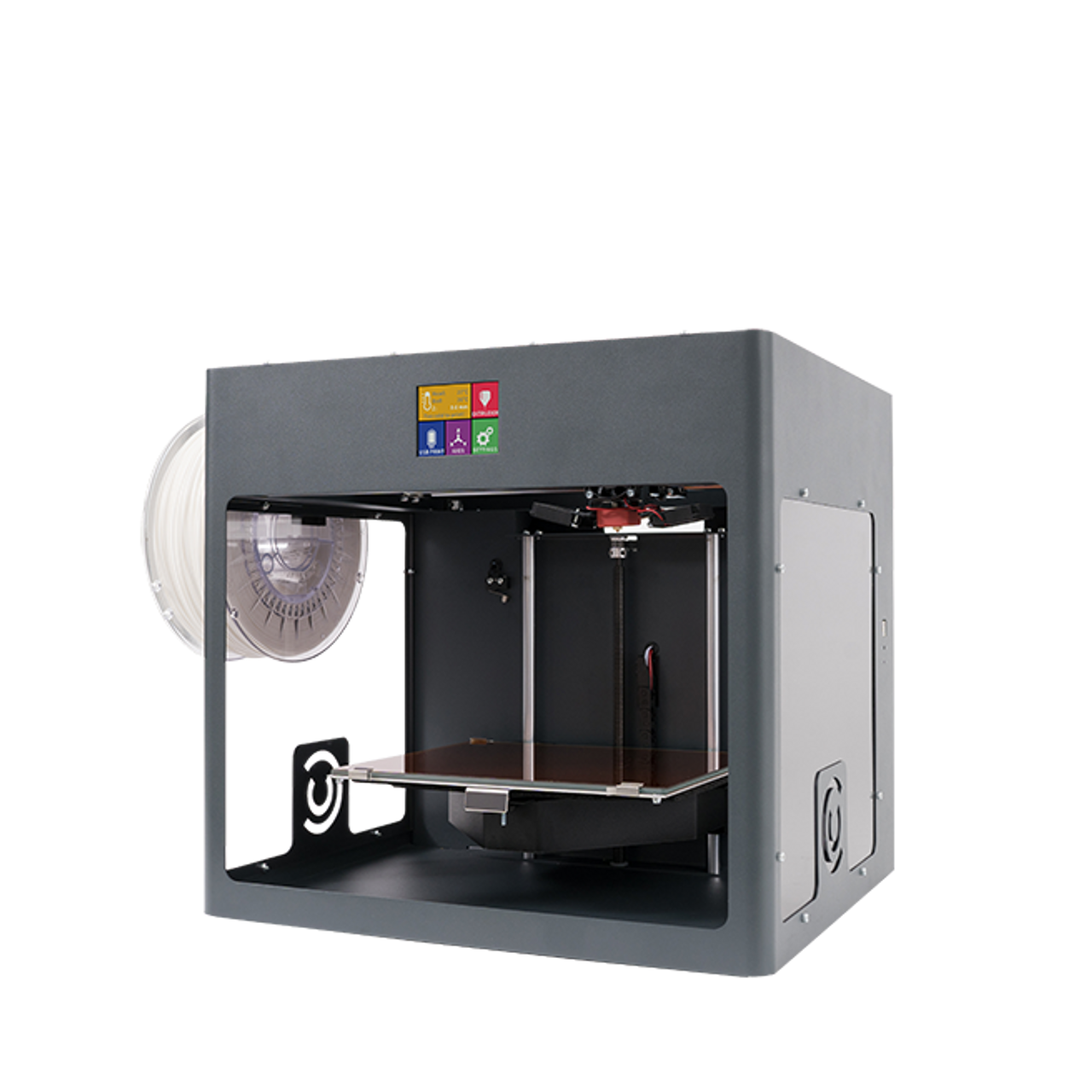

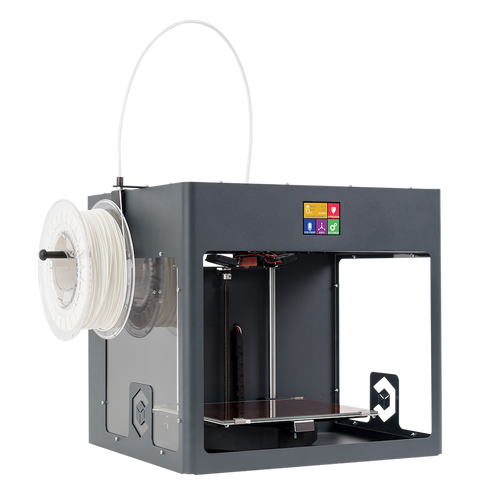

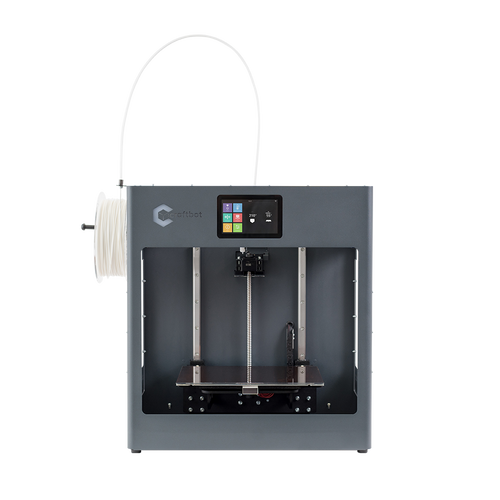

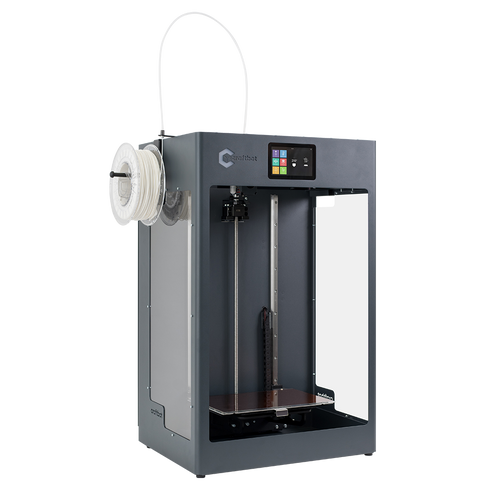

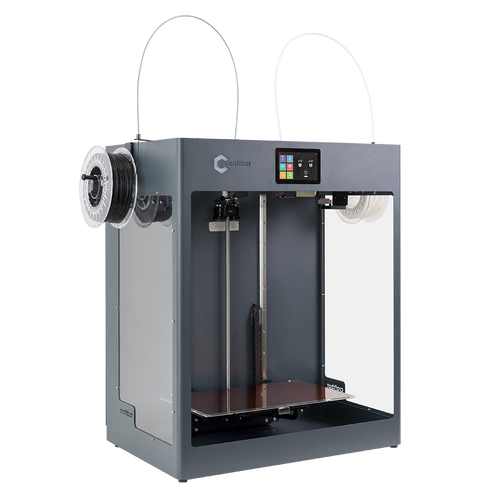

Craftbot Plus Pro Grey 3D Printer

CraftBot Plus Glass – upgraded with all metal hotend & glass build plate, FMS – add-on

The multi award-winning CraftBot Plus 3D printer was upgraded and from now on it is available with glass build plate and all-metal hotend for an even better printing experience.

Please note the FMS is not default feature!

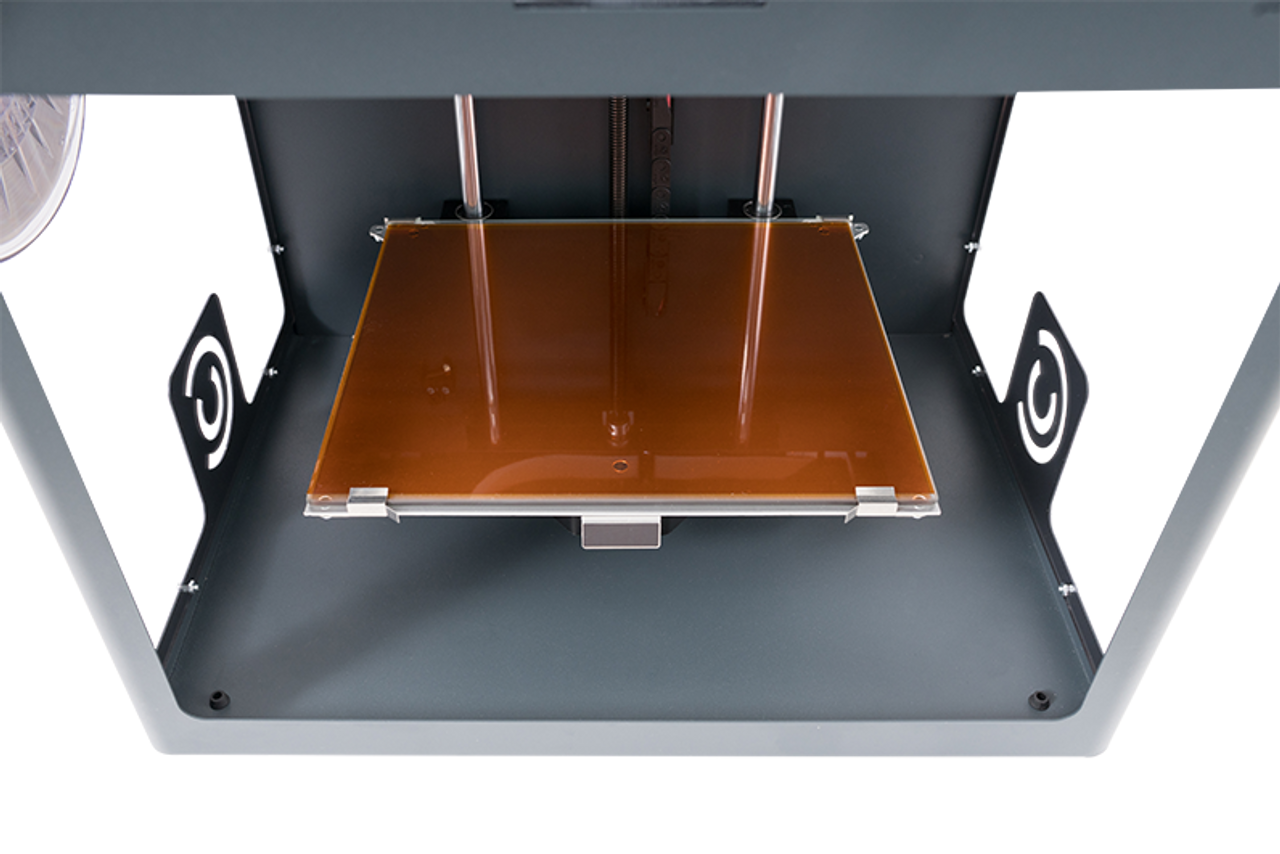

- Glass build plate:

FLATNESS: Print beds need to be flat throughout printing to avoid running into errors. Glass has a high modulus of elasticity and is thermally stable. Therefore, it remains flat and will ensure the bed’s leveling remains consistent throughout.

SMOOTH FINISH: Most of the user want the bottom of their prints to be as soft as possible; glass guarantees such a finish, giving a mirror-like, glossy base that cannot be achieved by most bed surfaces.

THERMAL CONDUCTIVITY: There are instances where the build platform needs to be heated to prevent warping and to improve print quality. thermal conductivity means you have a thermally stable platform that will not be affected by sudden rises or drops in temperature.

DURABILITY: Durable glass like tempered glass will not easily shatter or crack when exposed to high strains because it is manufactured to be more tolerant.

SCRATCH RESISTANCE: Beds like acrylic can easily get scratched and become a nuisance when printing. However, tempered glass tends to be scratch resistant and is not susceptible to abrasive or chemical damage. - All metal hotend:

LESS FILAMENT JAM: Fewer parts and connection points make jams less likely and much easier to clear.

BETTER PRINTING QUALITY: Thanks to the attribution of the all metal the CraftBot is able to print in better quality and making it perfect to use with more special filaments as well. Like wood and brass filaments.

IMPROVED COOLING SYSTEM: All-metal hotends have active cooling in order to isolate the melt zone. A smaller, more controlled melt zone provides cleaner retractions and less oozing for better print quality. - Filament Monitoring System (Add-on)

The filament monitoring system (FMS) supervises filament consumption, starts immediate troubleshooting when a filament jam is detected and messages the user in case there’s a need for intervention.